As consumer demand for safer, more efficient, and environmentally friendly food packaging grows, companies are increasingly turning to innovative materials and additives to enhance packaging properties. One such key component is the nucleating agent. Nucleating agents play an essential role in enhancing the performance, quality, and sustainability of packaging materials. In this article, we will delve into what nucleating agent are, their specific functions in food packaging, and why they matter for both producers and consumers.

What is a Nucleating Agent?

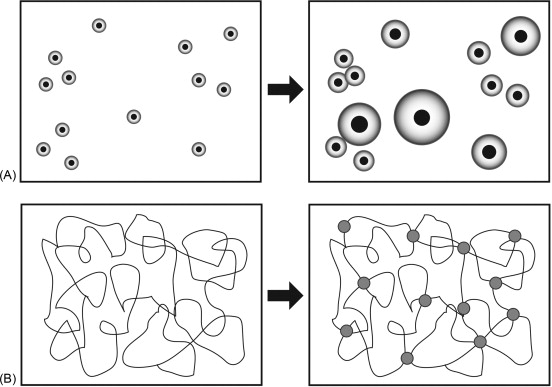

A nucleating agent is a substance added to polymers during the manufacturing process to control the crystallization rate and enhance the material’s properties. These agents work by creating nucleation points, or “seeds,” where polymer crystals can form and grow. By controlling the crystallization process, nucleating agents influence the structure, transparency, mechanical strength, and thermal stability of packaging materials.

In the context of food packaging, these improved properties can mean longer-lasting, safer, and more visually appealing packaging.

How Nucleating Agents Improve Food Packaging

Food packaging needs to meet high standards to ensure food safety, durability, and sustainability. Here are some of the primary benefits of using nucleating agents in food packaging:

1. Enhanced Mechanical Properties

Nucleating agents improve the mechanical strength of plastic materials by refining their crystalline structure. This results in:

- Increased stiffness: This is particularly useful in creating rigid containers that can hold up under pressure, like juice bottles and yogurt cups.

- Improved impact resistance: Stronger materials are less likely to crack or break, ensuring that food remains safe and uncontaminated during transport and storage.

2. Improved Thermal Stability

Adding a nucleating agent can increase the thermal stability of packaging materials, making them more resistant to changes in temperature. This is especially beneficial for food items that undergo pasteurization or sterilization, as the packaging must withstand higher temperatures without degrading. Thermal stability is also essential for products that need to be stored in hot or cold environments, such as frozen foods or microwavable meals.

3. Enhanced Clarity and Transparency

In food packaging, transparency is often a desirable quality as it allows consumers to see the product inside. Nucleating agents help produce more uniform and smaller crystals in polymer materials, leading to improved clarity. This enhancement is particularly important for packaging fresh produce, meat, and dairy products, as it allows customers to inspect the quality of the food before purchasing.

4. Reduced Production Costs and Environmental Impact

Nucleating agents can lead to shorter cooling times in the manufacturing process, which reduces energy consumption and production costs. Additionally, they can allow for thinner packaging without sacrificing durability, leading to less material usage and waste. This contributes to a more environmentally friendly production process, aligning with the growing consumer and regulatory demand for sustainable packaging solutions.

Common Types of Nucleating Agents Used in Food Packaging

There are several types of nucleating agents commonly used in the food packaging industry, each with unique properties and benefits. Here are some of the most widely used:

1. Organic Nucleating Agents

These agents are often derived from natural sources, making them a popular choice for eco-friendly packaging solutions. Organic nucleating agents can enhance transparency and are effective in reducing crystallization time, which can speed up the production process.

2. Inorganic Nucleating Agents

Inorganic agents, like talc and calcium carbonate, are effective in enhancing the rigidity and thermal stability of packaging materials. They are commonly used in products that require higher strength and temperature resistance, such as bottles, lids, and containers for hot food items.

3. Hybrid Nucleating Agents

Hybrid nucleating agents combine properties from both organic and inorganic sources. This type of agent offers a balance between transparency, strength, and thermal resistance, making it suitable for a broad range of food packaging applications. These agents are particularly useful in packaging that needs to maintain flexibility and durability, like plastic wraps and resealable bags.

Why Are Nucleating Agents Important for Food Safety?

Ensuring food safety is one of the primary concerns of the packaging industry, and nucleating agent can play a significant role in this regard. Here’s how:

- Prevention of Contamination: By enhancing the strength and durability of packaging materials, nucleating agents reduce the chances of breakage and contamination.

- Extended Shelf Life: Packaging with enhanced thermal stability helps maintain the quality and freshness of food, reducing spoilage and waste.

- Consumer Protection: Transparent packaging allows consumers to inspect the food’s condition, helping them make informed purchasing decisions.

Future Trends: The Role of Nucleating Agents in Sustainable Packaging

With the increasing focus on sustainability, the role of nucleating agents is expanding. Researchers and manufacturers are exploring bio-based nucleating agents that can reduce the environmental footprint of food packaging. The development of nucleating agents from renewable resources can make a significant impact, contributing to both improved packaging performance and environmental protection.

In addition, the use of nucleating agents in bioplastics, like polylactic acid (PLA), is gaining traction. PLA is derived from renewable sources such as corn starch and sugarcane, and nucleating agents help improve its strength and usability, making it a promising material for sustainable food packaging.

Conclusion

Nucleating agents are critical in modern food packaging, contributing to improved durability, transparency, thermal stability, and sustainability. By enhancing the material properties, they not only improve food safety but also help reduce the environmental impact of packaging. As the packaging industry moves toward more sustainable solutions, nucleating agents will continue to play a pivotal role, making food packaging safer, stronger, and more eco-friendly.

Understanding the role and benefits of nucleating agents can help consumers, manufacturers, and regulators make informed choices that lead to better food safety and sustainability in the long run.